- info@nuaflex.com

- +90 (216) 606 65 94

Nuaflex delivers an extensive portfolio of industrial metal hoses, meticulously engineered to excel in the most demanding and diverse applications. From simple fluid transfer to the conveyance of corrosive chemicals at extreme temperatures, our hoses provide the critical reliability and durability modern industry requires. This guide details our core industrial hose products, all of which are designed to meet specific operational challenges and comply with DIN EN ISO 10380 standards.

| SNF: STANDARD CORRUGATED HOSE DIMENSIONS DATA SHEET | ||||||||||

| DN | Inch | Model | Internal Diameter | Outside Diameter | Tolerance | Minimum Bending Radius | Nominal Bending Radius | Nominal Pressure DIN EN ISO 10380/SF4 | |||

| [mm] | [mm] | [mm] | rmin [mm] | rn [mm] | PN [bar] | ||||||

| 6 | 1/4″ | Non-braided | 6.3 | 9.6 | ± 0,20 | 15 | 80 | 24 | |||

| Braided | 11.3 | 25 | 150 | ||||||||

| 8 | 5/16″ | Non-braided | 8.3 | 12.4 | ± 0,20 | 16 | 125 | 17 | |||

| Braided | 13.8 | 32 | 140 | ||||||||

| 10 | 3/8″ | Non-braided | 9.8 | 14.2 | ± 0,20 | 18 | 130 | 12 | |||

| Braided | 15.7 | 38 | 105 | ||||||||

| 12 | 1/2″ | Non-braided | 12.5 | 16.7 | ± 0,20 | 20 | 139 | 9 | |||

| Braided | 17.6 | 45 | 70 | ||||||||

| 16 | 5/8″ | Non-braided | 16.0 | 21.2 | ± 0,20 | 28 | 165 | 7 | |||

| Braided | 23.2 | 58 | 65 | ||||||||

| 20 | 3/4″ | Non-braided | 20.5 | 26.7 | ± 0,20 | 32 | 175 | 6 | |||

| Braided | 28.2 | 70 | 55 | ||||||||

| 25 | 1″ | Non-braided | 25.5 | 31.7 | ± 0,30 | 40 | 190 | 3 | |||

| Braided | 33.6 | 85 | 49 | ||||||||

| 32 | 1 1/4″ | Non-braided | 34.0 | 41.3 | ± 0,30 | 50 | 260 | 2.5 | |||

| Braided | 43.5 | 95 | 35 | ||||||||

| 40 | 1 1/2″ | Non-braided | 40.2 | 49.9 | ± 0,30 | 60 | 300 | 2 | |||

| Braided | 52.3 | 130 | 30 | ||||||||

| 50 | 2″ | Non-braided | 50.4 | 60.3 | ± 0,40 | 70 | 320 | 1.6 | |||

| Braided | 62.5 | 160 | 26 | ||||||||

| 65 | 2 1/2″ | Non-braided | 66.1 | 77.0 | ± 0,50 | 115 | 460 | 1.3 | |||

| Braided | 80.5 | 200 | 25 | ||||||||

| 80 | 3″ | Non-braided | 80.2 | 95.1 | ± 0,50 | 130 | 660 | 1.5 | |||

| Braided | 97.9 | 240 | 16 | ||||||||

| 100 | 4″ | Non-braided | 100.1 | 116.3 | ± 0,50 | 160 | 750 | 1 | |||

| Braided | 119.6 | 290 | 10 | ||||||||

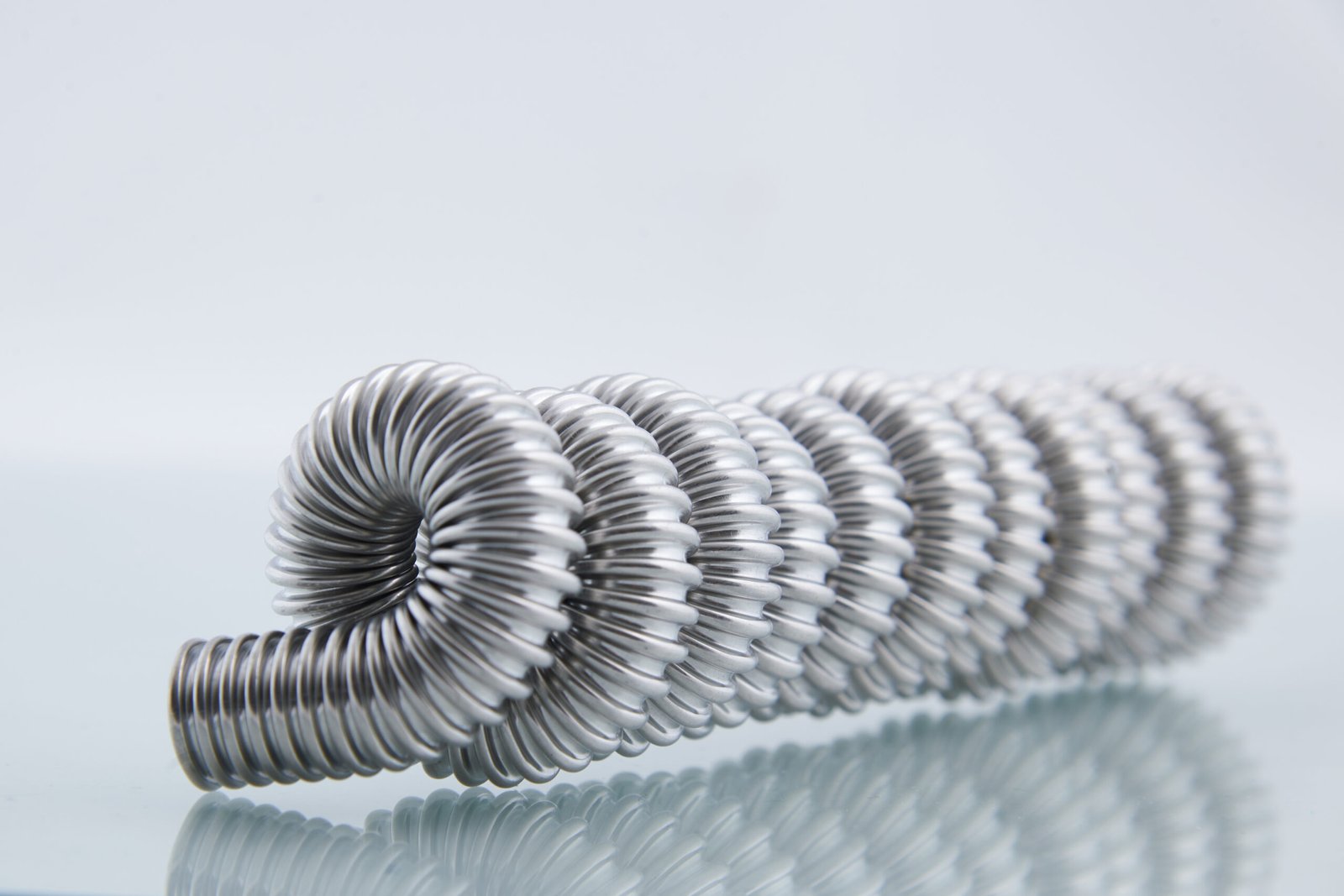

The NUAFLEX Standard is our flagship, a versatile and mechanically formed corrugated hose designed for a broad spectrum of fluid transfer applications. Its engineered design offers an optimal balance of flexibility and robust strength.

Key Features:

|

WNF: WIDE PITCH CORRUGATED HOSE DIMENSIONS DATA SHEET | ||||||||||

| DN | Inch | Model | Internal Diameter | Outside Diameter | Tolerance | Minimum Bending Radius | Nominal Bending Radius |

Nominal Pressure DIN EN ISO 10380/SF4 |

|||

| [mm] | [mm] | [mm] | rmin [mm] | rn [mm] | PN [bar] | ||||||

| 12 | 1/2″ | Non-braided | 12.0 | 16.3 | ± 0.20 | 20 | 100 | 21 | |||

| 16 | 5/8″ | Non-braided | 16.5 | 21.3 | ± 0.20 | 25 | 120 | 16 | |||

| 20 | 3/4″ | Non-braided | 20.8 | 26.2 | ± 0.20 | 30 | 160 | 10 | |||

| 25 | 1″ | Non-braided | 25.8 | 31.5 | ± 0.30 | 35 | 200 | 9 | |||

| 32 | 1 1/4″ | Non-braided | 33.8 | 40.2 | ± 0.30 | 40 | 380 | 4 | |||

| 40 | 1 1/2″ | Non-braided | 40.6 | 49.5 | ± 0.30 | 65 | 500 | 3.5 | |||

| 50 | 2″ | Non-braided | 50.7 | 60.1 | ± 0.40 | 75 | 650 | 3 | |||

The NUAFLEX Wide features a broader corrugation pitch, resulting in a lighter hose with specific advantages for applications requiring easier cleaning and lower pressure drop.

Key Features:

High-Flexibility Corrugated Metal Hose (NUAFLEX Extra)

The N-FLEX Pro is engineered for maximum flexibility and dynamic performance. Its closed-pitch corrugation design makes it the ideal solution for applications involving significant movement, vibration, and tight bending radii.

Key Features:

| HSNF: HIGH PRESSURE STANDARD CORRUGATED HOSE DIMENSIONS DATA SHEET | ||||||||||

| DN | Inch | Model | Internal Diameter | Outside Diameter | Tolerance | Minimum Bending Radius | Nominal Bending Radius | Nominal Pressure DIN EN ISO 10380/SF4 | |||

| [mm] | [mm] | [mm] | rmin [mm] | rn [mm] | PN [bar] | ||||||

| 6 | 1/4″ | Non-braided | 6.1 | 9.5 | ± 0,20 | 17 | 110 | 40 | |||

| Braided | 11.3 | 25 | 180 | ||||||||

| 8 | 5/16″ | Non-braided | 8.3 | 12.4 | ± 0,20 | 16 | 130 | 50 | |||

| Braided | 13.8 | 32 | 200 | ||||||||

| 10 | 3/8″ | Non-braided | 9.5 | 14.1 | ± 0,20 | 18 | 130 | 25 | |||

| Braided | 15.7 | 38 | 105 | ||||||||

| 12 | 1/2″ | Non-braided | 12.4 | 16.8 | ± 0,20 | 20 | 139 | 7 | |||

| Braided | 17.8 | 45 | 70 | ||||||||

| 16 | 5/8″ | Non-braided | 16.3 | 21.8 | ± 0,20 | 28 | 195 | 17 | |||

| Braided | 23.3 | 58 | 65 | ||||||||

| 20 | 3/4″ | Non-braided | 19.9 | 26.3 | ± 0,20 | 32 | 285 | 7 | |||

| Braided | 28.2 | 70 | 55 | ||||||||

| 25 | 1″ | Non-braided | 25.2 | 31.6 | ± 0,30 | 40 | 360 | 6 | |||

| Braided | 34.1 | 95 | 49 | ||||||||

| 32 | 1 1/4″ | Non-braided | 33.0 | 41.0 | ± 0,30 | 50 | 380 | 4 | |||

| Braided | 43.3 | 105 | 35 | ||||||||

| 40 | 1 1/2″ | Non-braided | 40.1 | 49.8 | ± 0,30 | 60 | 430 | 2.5 | |||

| Braided | 51.8 | 130 | 50 | ||||||||

| 50 | 2″ | Non-braided | 50.7 | 60.2 | ± 0,40 | 70 | 490 | 2.5 | |||

| Braided | 63.5 | 160 | 26 | ||||||||

The NUAFLEX HD is a heavy-duty evolution of our standard hose, featuring a thicker wall for increased durability and pressure resistance in severe service conditions.

Key Features:

|

HWNF: WIDE PITCH BOILER CORRUGATED HEAT EXCHANGER HOSE DIMENSIONS DATA SHEET | ||||||||||

| DN | Inch | Model | Internal Diameter | Outside Diameter | Tolerance | Minimum Bending Radius | Surface Area |

Nominal Pressure DIN EN ISO 10380/SF4 |

|||

| [mm] | [mm] | [mm] | rmin [mm] | [m²/m] | PN [bar] | ||||||

| 16 | 5/8″ | Non-braided | 16.3 | 21.7 | ± 0.30 | 25 | 0.119 | 16 | |||

| 20 | 3/4″ | Non-braided | 20.1 | 26.2 | ± 0.30 | 30 | 0.145 | 12 | |||

| 25 | 1″ | Non-braided | 25.2 | 31.5 | ± 0.30 | 35 | 0.178 | 10 | |||

| 32 | 1 1/4″ | Non-braided | 33.1 | 40.1 | ± 0.40 | 40 | 0.230 | 6 | |||

| 40 | 1 1/2″ | Non-braided | 40.6 | 49.5 | ± 0.50 | 50 | 0.283 | 6 | |||

| 50 | 2″ | Non-braided | 50.7 | 60.1 | ± 0.50 | 78 | 0.348 | 6 | |||

The NUAFLEX HD-Wide combines the benefits of a wide corrugation with a heavy-duty, thicker wall construction, delivering exceptional robustness in demanding, high-flow applications.

Key Features:

Nuaflex industrial hoses are designed for a wide range of applications including industrial systems, machinery connections, fluid transfer, and high-performance installations.

Yes. Nuaflex industrial hoses are engineered to withstand high temperatures and pressure levels, depending on the hose type and application requirements.

Nuaflex industrial hoses are manufactured in accordance with relevant international standards such as DIN EN 10380, ensuring safety, durability, and long service life.

Yes. Nuaflex offers customized industrial hose solutions based on project needs, including different lengths, diameters, and connection options.